Process Intensification

Process Intensification is the improvement of a process in terms of energy efficiency, cost-effectiveness, size, speed or some other enhancement. In chemical engineering and reactors this often takes the form of applying energy to a fluid in order to decrease reaction time, size and cost while simultaneously increasing quality and yield. The ShockWave Power Reactor is a great tool for process intensification and creating continuous flow reactors through superior mass transfer.

The SPR uses the powerful forces of cavitational shockwaves to increase mass transfer and accelerate reations. Using the forces of process intensification, the SPR can convert many traditional batch reactions limited by poor mass transfer to true continuous operations. Safety can also be enhanced due to limiting volumes of dangerous components in contact or under reaction conditions.

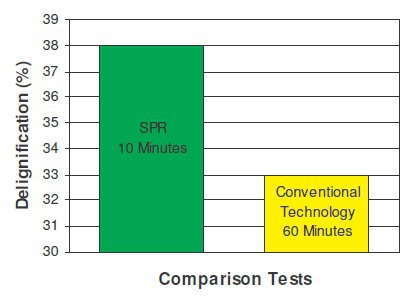

Below is one such example of process intensification from the pulp and paper industry. Oxygen delignification (a form a bleaching) typically takes 60-90 minutes and is conducted in large high temperature and high pressure stainless steel reactors. The ShockWave Power Reactor is able to provide process intensification and perform the same reaction to a higher yield in less time.

The ShockWave Power Reactor was recognized in Chemical Processing Magazine in a feature on process intensification devices which you can read below. The ShockWave Power Reactor portion begins on page 3.

http___www.chemicalprocessing.com_articl[...]

Adobe Acrobat document [307.2 KB]