Hydration

The SPR allows for complete and continuous hydration of gums and powders. This results in superior products with superior viscosity and/or raw material savings. This means continuous hydration using less dry powder producing a higher quality gel with less "fish eyes" for superior performance.

Using the microscopic and macroscopic pressure fluctuations of cavitation within the SPR allows for many benefits in hydration. Some of these benefits include:

- Cost reduction and/or increased viscosity due to higher hydration yield

- Elimination or reduction of the need for costly secondary solvents

- Reduced temperatures required for complete hydration

- Less shear damage due to the low shear environment of the cavitation zone

- Improved homogeneity and thus quality of the final product

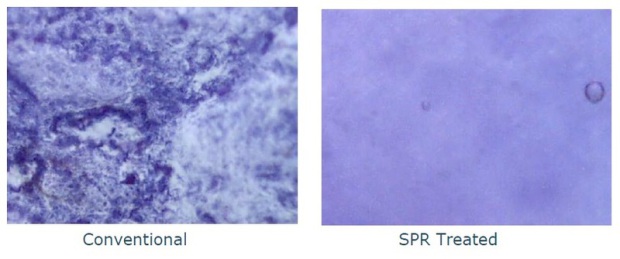

Conventional technologies for hydrating polymers to produce viscosifiers generally include mixing powdered polymer with water in a bulk mixer and then allowing the mixture to age before being added to a fluid to be viscosified. Traditional mixers used for this process often expose the polymer molecules to high shear stresses, which can damage and break apart a significant portion of the polymer molecule chains. To address this problem, traditional polymer hydrators often attempt reduce polymer chain damage by using elevated temperatures, mixing more slowly for long periods of time, adding secondary solvents to the mixture, or simply adding excess polymer to make up for damage and consequent incomplete hydration.

The SPR utilizes the power of cavitation shockwaves to induce microscopic and macroscopic pressure fluctuations within the mixture, while maintaining a low shear environment. The shockwaves and pressure fluctuations first separate and disperse individual particles of powder within the mixture allowing water to contact the powder particles on all sides. This maximizes the surface contact area between the water molecules and polymer chains. As the polymer chains in the particles begin to hydrate with water, the pressure fluctuations drive the water molecules into and out of the particles. This, in turn, detangles, releases, separates, and straightens the individual polymer molecule chains found in each particle of the powder. The cavitation induced pressure fluctuations serve to straighten, untangle, and stretch the polymer chains more fully, resulting in more complete hydration and viscosity development when compared to conventional shear mixing. The result is a greatly improved completeness of hydration with minimal damage to the resulting hydrated polymer chains.