Scale-Free Heating

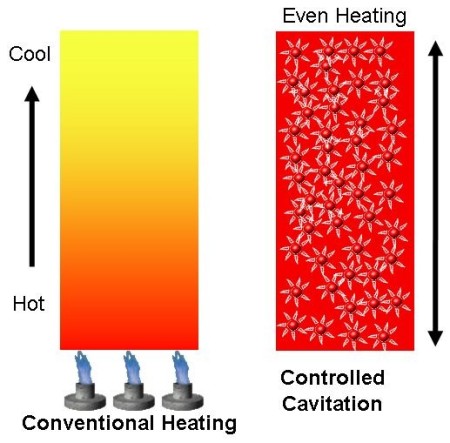

The ShockWave Power™ Reactor harnesses cavitation to heat liquids in seconds, whether in batch or continuous systems. This heating can be done with pinpoint accuracy and consistently by varying rpms through a temperature controller and variable frequency drive. There is no temperature gradient or hot or cold spots. There is also no heat transfer surface so there is no scaling or fouling. The system is flameless and can be totally automated.

The SPR can heat liquids with no degradation in the heat transfer coefficient. This was demonstrated in work conducted with a major university on a scaling liquid in a heating test cell.

Additionally, there is an ultrasonic cleaning effect that occurs on the metal surfaces inside the SPR™ Reactor as the shockwaves are generated within narrow clearances. This cleaning effect, in conjunction with a negative delta T between metal and liquid, ensures scale-free heating.